Combination square how do we use it in agriculture – Combination Square: Agricultural Uses explores the versatile applications of this precision tool in farming and agricultural settings. Beyond its common uses in woodworking and construction, the combination square offers farmers and agricultural workers a surprisingly effective means for accurate measurements, leveling, and alignment in various tasks. This guide details its functionality in leveling equipment, aligning irrigation systems, marking precise planting points, and constructing or repairing farm structures.

We’ll examine specific techniques, compare its accuracy to other tools, and provide maintenance tips to ensure its continued precision.

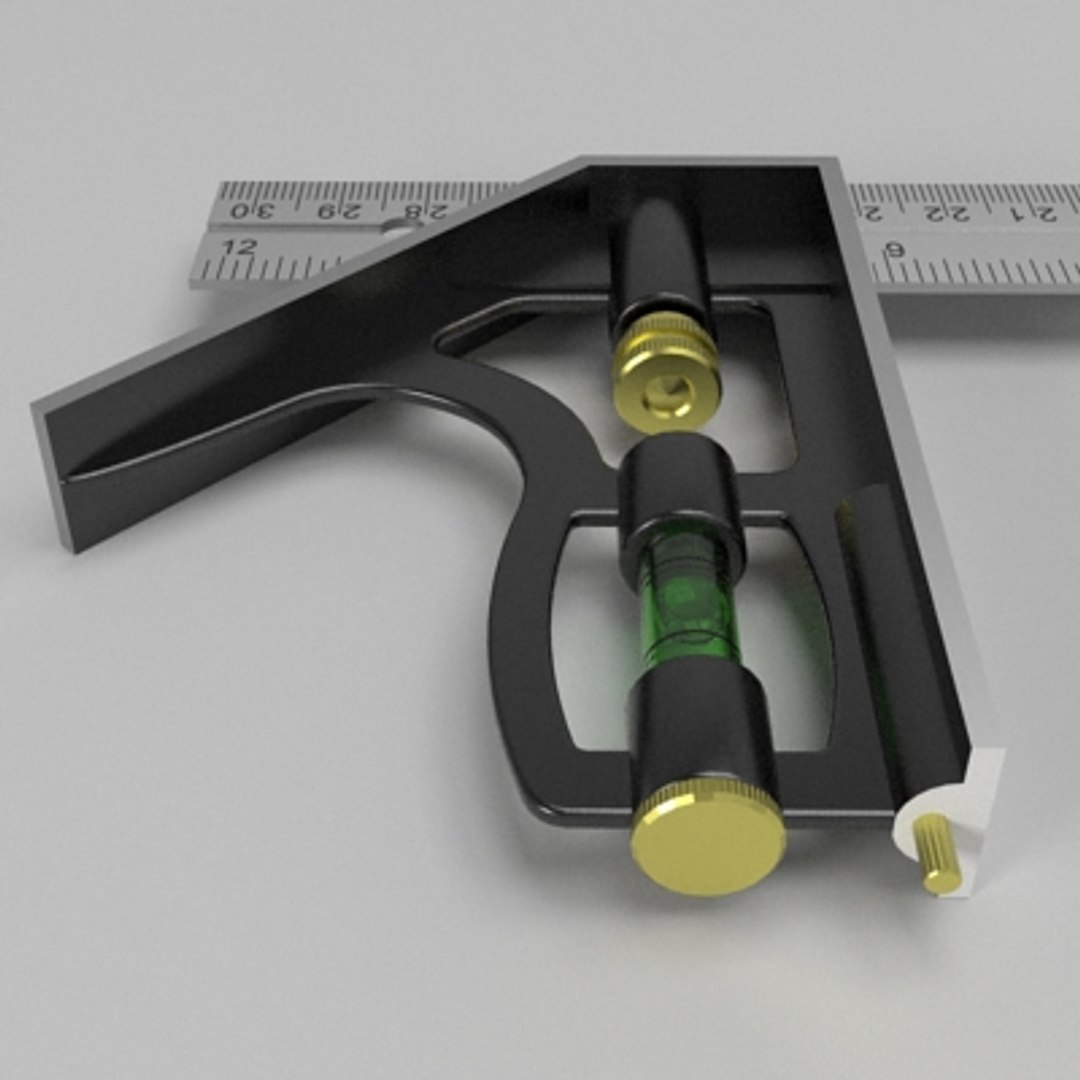

The combination square, a seemingly simple tool, comprises a head with a square head, a protractor, and a sliding rule. Its variations include different lengths and materials, influencing its application in different agricultural contexts. Understanding its components and how to use each feature effectively is crucial for maximizing its utility in diverse agricultural scenarios. From ensuring the levelness of a tractor to precisely marking planting rows, the combination square proves an invaluable asset for enhancing efficiency and accuracy in various agricultural practices.

Introduction to Combination Squares

Combination squares are versatile precision measuring tools widely used in various fields, including carpentry, metalworking, and agriculture. They offer a combination of functions in a single, compact tool, making them efficient and convenient for a range of tasks. Understanding their components and usage is crucial for accurate measurements and efficient work.Combination squares consist of a few key parts working together.

The main components are a blade, a head, and a sliding rule. The blade, typically made of hardened steel, is graduated in inches and/or millimeters, providing a precise measuring scale. The head, which houses the blade, is capable of being rotated and locked at 90° and 45° angles, facilitating accurate angle measurement and marking. The sliding rule allows the blade to be adjusted along its length, permitting the user to measure from different points and transfer measurements effectively.

Combination Square Components and Variations

The basic components—blade, head, and sliding rule—are common to all combination squares. However, variations exist in blade length, material, and the inclusion of additional features. Blade lengths range from 6 inches to 24 inches or more, depending on the intended application. Some blades are made of stainless steel for increased corrosion resistance, while others incorporate markings for specific applications, such as miter angles or plumb lines.

Some combination squares include a spirit level incorporated into the head, providing an additional function for checking vertical and horizontal alignment. The material of the head can also vary, with options including cast iron or hardened steel. Finally, the sliding rule might have additional markings or features to aid in specific tasks.

Principles of Accurate Measurement with a Combination Square

Accurate measurement using a combination square relies on proper technique and understanding of its capabilities. First, ensure the blade is securely locked in the head at the desired angle. When measuring length, firmly hold the square against the workpiece, ensuring the blade is in contact with the surface. For precise measurements, it’s crucial to align the zero mark of the blade with the starting point.

Read the measurement from the blade’s scale at the end point, taking care to avoid parallax error—viewing the scale at an angle. When using the square to mark angles, the head’s locking mechanism is essential. Lock the head at the required angle (90° or 45° typically), and use the blade to scribe a line accurately. Regular cleaning and maintenance of the combination square are vital to maintaining its accuracy and extending its lifespan.

Avoid dropping or striking the tool, as this can damage the blade and affect the precision of its measurements.

Agricultural Applications

The combination square, a versatile tool typically used in woodworking and metalworking, finds unexpected utility in agriculture, primarily for tasks requiring precise leveling and alignment. Its ability to quickly and accurately measure angles and levels makes it a valuable asset for various agricultural operations, improving efficiency and ensuring the proper functioning of equipment and infrastructure. This section details specific agricultural applications focusing on leveling and alignment tasks.

Accurate leveling and alignment are critical for optimal performance and longevity of agricultural machinery and infrastructure. Improper leveling can lead to uneven planting, reduced yields, inefficient irrigation, and damage to equipment. The combination square, with its integrated level and measuring capabilities, provides a simple yet effective solution for achieving the necessary precision in these applications.

Leveling Agricultural Equipment

A combination square can be used to ensure the levelness of various pieces of agricultural equipment. For example, to level a tractor, the square can be placed on the tractor’s hitch or other flat surface. The bubble level on the combination square will indicate if the surface is level. Adjustments can then be made to the tractor’s leveling mechanism until the bubble is centered.

Similarly, planters need to be level to ensure uniform seed depth and spacing. By using the combination square’s level, one can check the levelness of the planter’s frame and make adjustments as needed. This same process applies to other equipment such as cultivators, harvesters, and sprayers. Ensuring the equipment is level prevents uneven wear and tear and improves operational efficiency.

Aligning Irrigation Systems

Precise alignment is crucial for efficient irrigation. Using the combination square’s square head and rule, one can ensure that irrigation pipes are installed at the correct angle and that sprinkler heads are aligned properly. The square head can be used to check for 90-degree angles when connecting pipes, while the rule can be used to measure distances and ensure consistent spacing.

This precision reduces water waste and optimizes crop hydration. Furthermore, the combination square can be used to check the levelness of irrigation channels and ditches, ensuring even water distribution across the field.

Precise Alignment of Agricultural Structures

The combination square plays a vital role in ensuring the precise alignment of various agricultural structures. When constructing barns, sheds, or greenhouses, the combination square can be used to check the squareness of corners and the plumbness of posts and beams. This helps ensure structural integrity and prevents issues such as uneven settling or structural weakness. Similarly, when erecting fences, the combination square can be used to ensure that fence posts are perfectly vertical and aligned, resulting in a straight and robust fence.

The combination square’s accuracy helps minimize errors during construction, leading to stronger, more durable structures.

Comparison of Leveling Tools

| Tool | Accuracy | Application | Advantages/Disadvantages |

|---|---|---|---|

| Combination Square | +/- 1/32 inch (0.8 mm) typically | Leveling equipment, aligning structures, checking angles | Advantages: Versatile, portable, affordable. Disadvantages: Limited range, not as precise as some electronic levels. |

| Spirit Level (with longer base) | +/- 1/16 inch (1.6 mm) typically | Leveling large surfaces, machinery | Advantages: Good for larger surfaces, relatively inexpensive. Disadvantages: Less versatile than combination square. |

| Laser Level | +/- 1/8 inch (3.2 mm) at 30 meters typically | Leveling large areas, construction | Advantages: High accuracy over long distances, self-leveling. Disadvantages: More expensive, can be affected by sunlight. |

| Digital Level | +/- 0.1 degrees typically | Precise angle measurement, leveling | Advantages: High accuracy, digital readout. Disadvantages: Can be more expensive, requires batteries. |

Agricultural Applications

The combination square’s precision makes it a valuable tool in various agricultural tasks, exceeding its common use in woodworking or metalworking. Its ability to accurately measure both distances and angles is crucial for efficient and effective agricultural practices, from planting and harvesting to constructing durable and functional structures. This section details the application of the combination square for precise measurements and marking in agricultural settings.

Accurate measurements are fundamental to successful agricultural operations. Inconsistent measurements can lead to reduced yields, inefficient resource utilization, and ultimately, lower profits. The combination square, with its multiple features, allows for quick and precise measurements in the field, minimizing errors and maximizing efficiency.

Measuring Distances and Angles

The combination square’s rule allows for direct measurement of distances. For instance, when spacing plants, the rule can be used to ensure consistent distances between rows and individual plants. The square head can then be used to check for squareness, ensuring that rows are perfectly aligned for optimal sunlight exposure and efficient irrigation. The blade’s ability to slide along the rule also facilitates measuring irregular shapes or distances around obstacles.

For example, measuring the distance along a curved row of vines or around a tree trunk is straightforward using the combination square’s sliding blade. Furthermore, the protractor head on the combination square allows for precise angle measurement, critical for tasks such as assessing the slope of land for drainage or determining the angle of cut for support beams in a greenhouse construction.

Marking Precise Points for Planting or Harvesting

Precise marking is essential for efficient planting and harvesting. The combination square’s square head can be used to accurately mark points for planting seeds or seedlings, ensuring uniform spacing and optimizing plant growth. The blade can be used as a marking tool, either by scratching a line on the ground or using it to guide a marking tool for more precise markings on wood or metal components for agricultural equipment.

Combination squares are valuable tools in agriculture, aiding in precise measurements for tasks like leveling irrigation systems or ensuring accurate fence post placement. The precision needed is similar to determining the correct number of spacers for a vehicle’s suspension, such as finding the answer to 1992 vette rear monspring how many spacer , though on a much smaller scale.

Returning to agricultural applications, the combination square’s ability to measure angles and distances ensures efficient and effective work.

For instance, marking points for planting trees in an orchard or marking the precise locations for installing irrigation systems can be done with high accuracy using the combination square. This precision minimizes wasted space and resources, while optimizing yields.

Creating Precise Cuts for Building Agricultural Structures

Constructing durable and functional agricultural structures, such as fences, sheds, or greenhouses, requires precise cuts. The combination square aids in achieving this accuracy. A step-by-step guide for using a combination square to create precise cuts for building a simple wooden fence post is as follows:

- Measure and Mark: Use the rule to measure the desired length of the fence post. Then, use the square head to mark a perpendicular line at the measured point, indicating the exact cutting location.

- Set the Blade: Adjust the blade of the combination square to the desired angle for the cut (e.g., 45 degrees for a miter cut). Secure the blade in place.

- Transfer the Mark: Use the combination square to transfer the angle marking to the wood, ensuring a precise and consistent angle for the cut.

- Make the Cut: Use a saw (hand saw or power saw) to make the cut along the marked line. The combination square helps maintain the accuracy of the cut.

This process ensures that all fence posts are cut to the same length and angle, resulting in a structurally sound and aesthetically pleasing fence. The same principle applies to cutting beams for a greenhouse frame or other agricultural structures, where precise angles are crucial for stability and longevity.

Agricultural Applications

The combination square’s precision and versatility extend beyond surveying and woodworking; it proves invaluable in the construction and repair of farm structures and equipment. Its ability to accurately measure angles, check squareness, and ensure plumbness makes it an essential tool for maintaining the integrity and functionality of agricultural infrastructure.The combination square facilitates precise measurements and accurate alignment, leading to stronger, more durable, and safer farm buildings and equipment.

Properly aligned structures resist damage from weather and stress, ensuring longevity and reducing the need for costly repairs. The combination square contributes significantly to this by providing the means for accurate construction and efficient troubleshooting.

Checking Squareness and Plumbness of Structures

The combination square’s square head and level vial are crucial for ensuring the squareness and plumbness of structures during construction and repair. When erecting a new barn or repairing a damaged shed, using the square head to check the right angles of corners and the level vial to verify verticality is paramount. Deviations from square or plumb can lead to structural weakness and instability.

By precisely measuring and correcting these deviations, the combination square ensures the longevity and safety of the structure. For example, ensuring the corner posts of a barn are perfectly square prevents racking and ensures the structural integrity of the entire building. Similarly, verifying the plumbness of support beams prevents uneven settling and potential collapse.

Common Agricultural Repair Tasks Utilizing a Combination Square

Accurate measurements are fundamental to successful agricultural repairs. The combination square’s diverse features allow for precise measurements of angles, lengths, and depths, improving repair quality and efficiency. It aids in diagnosing problems and ensures repairs are correctly executed.

- Repairing Damaged Wooden Fencing: The combination square helps to accurately measure angles for cutting replacement fence posts and rails, ensuring a straight and secure fence line. The square head ensures accurate joining of the components, preventing weakness in the fence structure.

- Building and Repairing Farm Gates: Ensuring the gate frame is square is essential for proper function. The combination square allows for precise measurement and alignment of the gate frame components, preventing binding and ensuring smooth operation. Accurate measurements are also crucial when replacing or repairing gate hinges and latches.

- Repairing Farm Equipment: Many farm implements have components that require precise alignment. The combination square can be used to check the squareness of welds, the alignment of shafts, and the accuracy of angles in various mechanical parts. For instance, ensuring the blades of a cultivator are perfectly aligned prevents uneven tillage and damage to the soil.

- Constructing and Repairing Animal Housing: When building or repairing animal housing structures, the combination square assists in creating square corners and plumb walls, which are crucial for structural integrity and animal safety. This ensures the structural soundness of the animal housing, preventing collapse and maintaining a safe environment.

Advanced Techniques and Specialized Uses

The combination square, while seemingly simple, offers a surprising level of versatility beyond basic measurements in agricultural settings. Its ability to perform multiple functions—as a square, a level, a depth gauge, and a marking tool—makes it valuable in various specialized applications where precision is crucial. Comparing its capabilities to other common agricultural tools reveals its unique strengths.The combination square’s advantages over other measuring tools stem from its integrated design.

Unlike a separate level and ruler, it combines these functions, saving time and reducing the chance of error introduced by using multiple tools. Compared to a tape measure, it provides greater accuracy for shorter distances and allows for precise marking of angles, critical for tasks involving precise cuts or alignments. While a protractor offers angle measurement, the combination square offers both angle measurement and a straight edge for marking, increasing efficiency.

Digital measuring tools may offer greater precision in certain instances, but the combination square’s robustness and simplicity make it preferable in harsh agricultural environments.

Comparison with Other Agricultural Measuring Tools

The combination square’s compact design and multi-functionality contrast with the often more specialized nature of other agricultural measuring tools. For instance, while a laser level provides highly accurate leveling over long distances, the combination square excels in close-quarters work and fine adjustments. Similarly, a measuring wheel is ideal for large area measurements, but lacks the combination square’s precision for smaller, intricate tasks.

The combination square fills a niche between these specialized tools, providing a versatile and accurate solution for a range of measurement needs in a robust, durable package suitable for the often harsh conditions of agricultural work.

Specialized Applications in Niche Agricultural Practices

The combination square finds specialized applications in various niche agricultural practices requiring precise measurements. In viticulture, for example, it aids in ensuring the correct spacing and alignment of vines during planting and pruning. The square’s ability to measure angles precisely is crucial for creating trellises and ensuring optimal vine growth. In horticulture, the combination square aids in the construction of precise raised beds, ensuring uniform height and levelness for optimal drainage and plant health.

Similarly, in greenhouse construction, the combination square can be used for precise measurements during the building of support structures and the installation of irrigation systems.

Visual Representation of Combination Square Use in Agriculture

Imagine a farmer constructing a raised bed for vegetable cultivation. The farmer uses the combination square’s square head to ensure the frame is perfectly square, checking for 90-degree angles at each corner. Then, using the blade, the farmer measures the precise height of the frame sides, ensuring uniformity across all four sides. The level on the blade is then used to ensure the entire frame is perfectly level, ready for the addition of soil.

Key measurement points include the internal and external corners of the raised bed frame (verified for squareness), the height of each side of the frame (measured from the ground), and the overall levelness of the completed frame. This illustrates how the combination square’s multiple functions work together to ensure accuracy and efficiency in a common agricultural task.

Maintenance and Care of Combination Squares

Proper maintenance ensures the longevity and accuracy of a combination square, a valuable tool in both general and agricultural applications. Regular cleaning, careful storage, and prompt attention to any damage will significantly extend its lifespan and maintain its precision for accurate measurements. Neglecting these aspects can lead to inaccurate readings and ultimately, damage to the tool and potentially even the materials being measured.Regular cleaning prevents the accumulation of dirt, debris, and corrosive materials that can damage the square’s components.

Accurate measurements depend on the square’s surfaces remaining clean and free from obstructions.

Cleaning Procedures

To clean a combination square, first remove any loose dirt or debris with a soft brush. A compressed air canister can be helpful for removing particles from hard-to-reach areas. Then, wipe the blade and head with a clean, lint-free cloth dampened with a mild solvent such as mineral spirits or isopropyl alcohol. Avoid using harsh chemicals or abrasive cleaners, as these can damage the finish and potentially affect the accuracy of the measurements.

After cleaning, dry the tool thoroughly with a clean, dry cloth before storing it. Always ensure that all moving parts are free of debris to maintain smooth operation.

Storage Recommendations

Proper storage protects the combination square from damage and maintains its accuracy. Store the square in a dry, clean place, away from excessive heat, moisture, and direct sunlight. A protective case or sheath will further protect the blade from scratches and damage. If storing multiple squares, separate them to prevent accidental damage from rubbing against each other.

Keeping the square in a dedicated storage location prevents accidental damage or misplacement.

Addressing Common Problems and Damage

Identifying and addressing damage promptly minimizes further issues and maintains the accuracy of the tool.

Blade Damage

Minor scratches on the blade’s surface can usually be removed with fine polishing compound and a soft cloth. However, significant damage, such as bends or chips, often necessitates professional repair or replacement. A severely damaged blade will lead to inaccurate measurements and could cause further damage during use.

Loose or Damaged Head

If the head feels loose or wobbly, it may require tightening. Consult the manufacturer’s instructions for the proper procedure. Attempting to force adjustments without proper knowledge could cause further damage. A loose head can lead to inaccurate measurements and potentially damage to the square itself.

Maintaining Accuracy and Precision, Combination square how do we use it in agriculture

Regular checks and calibrations help maintain the accuracy of a combination square.

Regular Calibration Checks

Periodically check the square’s accuracy against a known standard. If inconsistencies are detected, professional calibration may be necessary. Regular calibration ensures continued accuracy and reliable measurements.

Proper Handling Techniques

Always handle the combination square with care to avoid dropping or impacting it. Avoid applying excessive force during measurements, as this can damage the blade or head. Proper handling minimizes the risk of damage and extends the lifespan of the tool.

Closing Summary: Combination Square How Do We Use It In Agriculture

The combination square, while often overlooked in agricultural contexts, demonstrates its value as a precise and versatile measuring and alignment tool. Its applications extend far beyond basic measurements, assisting in the leveling of equipment, precise alignment of structures, and accurate marking for planting and harvesting. By understanding its capabilities and employing proper maintenance techniques, farmers and agricultural workers can significantly improve the accuracy and efficiency of their operations.

This guide has highlighted key applications, offering practical techniques to maximize this tool’s potential in various agricultural tasks, contributing to improved yields and overall farm productivity.