Allison 4500 rds how many gears – Allison 4500 RDS: How many gears does this robust transmission possess? Understanding the gear count of the Allison 4500 RDS is crucial for operators and mechanics alike. This transmission, known for its reliability and performance in heavy-duty applications, employs a specific gear configuration designed for optimal power delivery and efficiency. This exploration delves into the specifics of the Allison 4500 RDS, examining its gear count, shifting mechanism, and overall operational characteristics.

The Allison 4500 RDS is a fully automatic transmission designed for medium-duty trucks, buses, and other heavy-duty vehicles. Its robust construction and advanced features make it a popular choice in demanding applications. This analysis will provide a comprehensive overview of its capabilities, including a detailed examination of its gear configuration and the technology behind its shifting mechanism.

Allison 4500 RDS Transmission Overview: Allison 4500 Rds How Many Gears

The Allison 4500 RDS is a robust, heavy-duty automatic transmission known for its reliability and performance in demanding applications. It’s a popular choice for medium-duty trucks and buses due to its durability and efficient power transfer. This overview will detail its specifications, applications, and compare it to similar transmissions from other manufacturers.

Allison 4500 RDS Specifications

The Allison 4500 RDS is a 5-speed fully automatic transmission designed for medium-duty applications. It features a rugged construction, incorporating durable components designed to withstand high torque and continuous operation. Key specifications include a torque capacity of up to 1250 lb-ft (1695 Nm), although the exact figure can vary based on the specific application and engine configuration. The transmission’s weight typically falls within the range of 500-600 lbs (227-272 kg), again subject to variations depending on the specific configuration and optional features.

Typical Applications of the Allison 4500 RDS

The Allison 4500 RDS finds its place in a variety of medium-duty vehicles. Common applications include refuse trucks, delivery trucks, school buses, and other vehicles requiring reliable power transfer and robust operation in challenging conditions. Its ability to handle high torque loads makes it suitable for applications involving frequent stops and starts, heavy payloads, and demanding terrains. The transmission’s electronic controls offer features such as electronic shifting and improved fuel efficiency compared to older mechanical transmissions.

Comparison with Similar Transmissions

The following table compares the Allison 4500 RDS to similar transmissions offered by other manufacturers. Note that torque capacity and specific applications can vary based on the exact model and configuration. Direct comparisons are challenging due to the variations in specific model offerings and configurations within each manufacturer’s lineup.

| Manufacturer | Model | Torque Capacity (lb-ft) | Typical Applications |

|---|---|---|---|

| Allison Transmission | 4500 RDS | Up to 1250 | Refuse trucks, delivery trucks, school buses |

| ZF | 6HP | Varies by model (approx. 800-1200) | Medium-duty trucks, buses |

| Meritor | Various models | Varies significantly by model | Medium- and heavy-duty trucks, buses |

| Voith | Various models | Varies significantly by model | Heavy-duty applications, including buses and specialized vehicles |

Gear Count and Shifting Mechanism

The Allison 4500 RDS transmission is a robust and reliable automatic transmission commonly used in heavy-duty applications. Understanding its gear count and shifting mechanism is crucial for optimal performance and maintenance. This section details the specifics of the Allison 4500 RDS’s gear selection process.The Allison 4500 RDS features five forward gears and one reverse gear. This gear configuration is designed to provide a balance between fuel efficiency at highway speeds and sufficient power for low-speed maneuvers and heavy loads.

The transmission utilizes an electronically controlled shifting mechanism, meaning gear changes are managed by an electronic control unit (ECU) rather than a manual lever.

Shifting Mechanism Details

The Allison 4500 RDS employs a sophisticated electronic control system to manage gear selection. The ECU continuously monitors various vehicle parameters, including engine speed, vehicle speed, throttle position, and load, to determine the optimal gear for any given driving condition. This system automatically selects the appropriate gear for maximum efficiency and performance, adapting to changing driving situations in real-time.

The system also incorporates shift scheduling to optimize gear changes for smoothness and reduced wear on the transmission components. This contrasts with older, manually shifted transmissions, requiring the driver to select gears.

The Allison 4500 RDS transmission is known for its robust design and reliability. Understanding its gear configuration is crucial for optimal performance; however, the precise number of gears depends on the specific application and configuration. This variability is somewhat akin to how others perceive you, as illustrated by the complexities of juggling priorities in the tarot card, 2 of pentacles as how someone sees you , where multiple factors influence the overall impression.

Returning to the Allison 4500 RDS, consulting the vehicle’s specifications will provide the definitive answer regarding its gear count.

Advantages of Electronic Shifting

Electronic shifting offers several advantages. The system ensures smooth, precise gear changes, minimizing driveline shock and maximizing fuel economy. The ECU’s ability to constantly monitor and adapt to changing conditions results in optimized gear selection for various driving situations, such as uphill climbs or heavy towing. Furthermore, electronic shifting eliminates the need for a manual clutch and shifter, simplifying operation and reducing driver fatigue, particularly in demanding applications.

Disadvantages of Electronic Shifting

While electronic shifting offers many advantages, some disadvantages exist. A malfunctioning ECU or related components can render the transmission inoperable, requiring specialized diagnostics and repairs. The complexity of the electronic system increases the potential for expensive repairs compared to simpler mechanical systems. Dependence on electronics also introduces a potential vulnerability to electrical interference or power failures. Finally, while sophisticated algorithms strive for optimal shifting, driver input or specific driving styles might not always be perfectly accommodated by the automatic system.

Gear Selection Process Flowchart, Allison 4500 rds how many gears

The gear selection process is complex, involving numerous factors. A simplified representation, however, could be visualized as follows:(Descriptive Flowchart Text): The flowchart would begin with a “Start” node. This would branch to a decision point: “Is the vehicle moving?” A “Yes” branch would lead to a series of decision points based on factors like vehicle speed, engine speed, throttle position, and load.

Each decision point would feed into a “Gear Selection” node that determines the appropriate gear (1-5). A “No” branch from “Is the vehicle moving?” would lead to a decision point: “Reverse required?” A “Yes” branch would select reverse gear; a “No” branch would remain in neutral. Finally, all gear selection paths would converge at an “Execute Gear Change” node, followed by an “End” node.

Operational Characteristics and Performance

The Allison 4500 RDS automatic transmission, designed for heavy-duty applications, exhibits performance characteristics heavily influenced by factors such as engine torque, vehicle weight, and operating conditions. Understanding these characteristics is crucial for maximizing efficiency and longevity. Its robust design allows for consistent performance across diverse operating scenarios.The Allison 4500 RDS is renowned for its smooth shifting and power transfer, particularly beneficial in demanding environments.

This is achieved through its sophisticated electronic controls and hydraulic system, which constantly adjust shift points based on real-time inputs. This results in optimal performance across various load conditions, from light cruising to heavy hauling.

Load Condition Performance

The 4500 RDS maintains consistent performance across varying load conditions. Under light loads, the transmission prioritizes fuel efficiency by utilizing higher gears. As load increases, the transmission seamlessly downshifts, providing the necessary torque for acceleration and maintaining speed on inclines. Under heavy loads, the transmission’s robust design ensures efficient power transfer, minimizing strain on the engine and drivetrain. The transmission’s ability to handle high torque outputs is a key factor in its suitability for heavy-duty applications such as refuse trucks and construction vehicles.

The electronic control system adapts to these changing loads, preventing harsh shifting and maximizing the engine’s power potential.

Optimal Operating Range for Fuel Efficiency

Achieving optimal fuel efficiency with the Allison 4500 RDS involves operating within the transmission’s optimal shift points. This is typically achieved at moderate engine speeds and loads. Aggressive acceleration and prolonged operation at high engine RPMs significantly reduce fuel economy. Maintaining consistent speeds and avoiding unnecessary braking also contributes to better fuel efficiency. Regular maintenance, including fluid changes and filter replacements, is also crucial for optimizing fuel economy.

Data from fleet operators show that consistent driving habits and preventative maintenance can improve fuel efficiency by up to 10% in certain applications.

Comparison to Other Allison Transmission Models

The Allison 4500 RDS occupies a specific niche within the Allison product line. Compared to smaller models like the 1000 series, the 4500 RDS offers significantly higher torque capacity and is designed for heavier vehicles. Compared to larger models like the 6-speed HD series, the 4500 RDS generally offers a simpler design and lower maintenance costs, making it a cost-effective choice for many applications.

The specific performance differences depend on the exact model being compared and the specific application. However, the 4500 RDS generally offers a balance of robust performance and manageable complexity.

Common Maintenance Procedures for Optimal Performance

Regular maintenance is essential for ensuring the long-term performance and reliability of the Allison 4500 RDS. Neglecting maintenance can lead to premature wear and costly repairs.

- Regular fluid and filter changes according to the manufacturer’s recommended schedule. This helps remove contaminants and maintain proper lubrication.

- Periodic inspection of the transmission for leaks, damage, or unusual noises. Early detection of problems can prevent major failures.

- Checking and adjusting transmission fluid levels as needed. Low fluid levels can severely damage the transmission.

- Regular inspection and adjustment of linkages and cables, ensuring proper shifting mechanism operation.

- Professional inspection and service every 250,000-500,000 miles or as recommended by the manufacturer, depending on operating conditions.

Technical Specifications and Diagrams

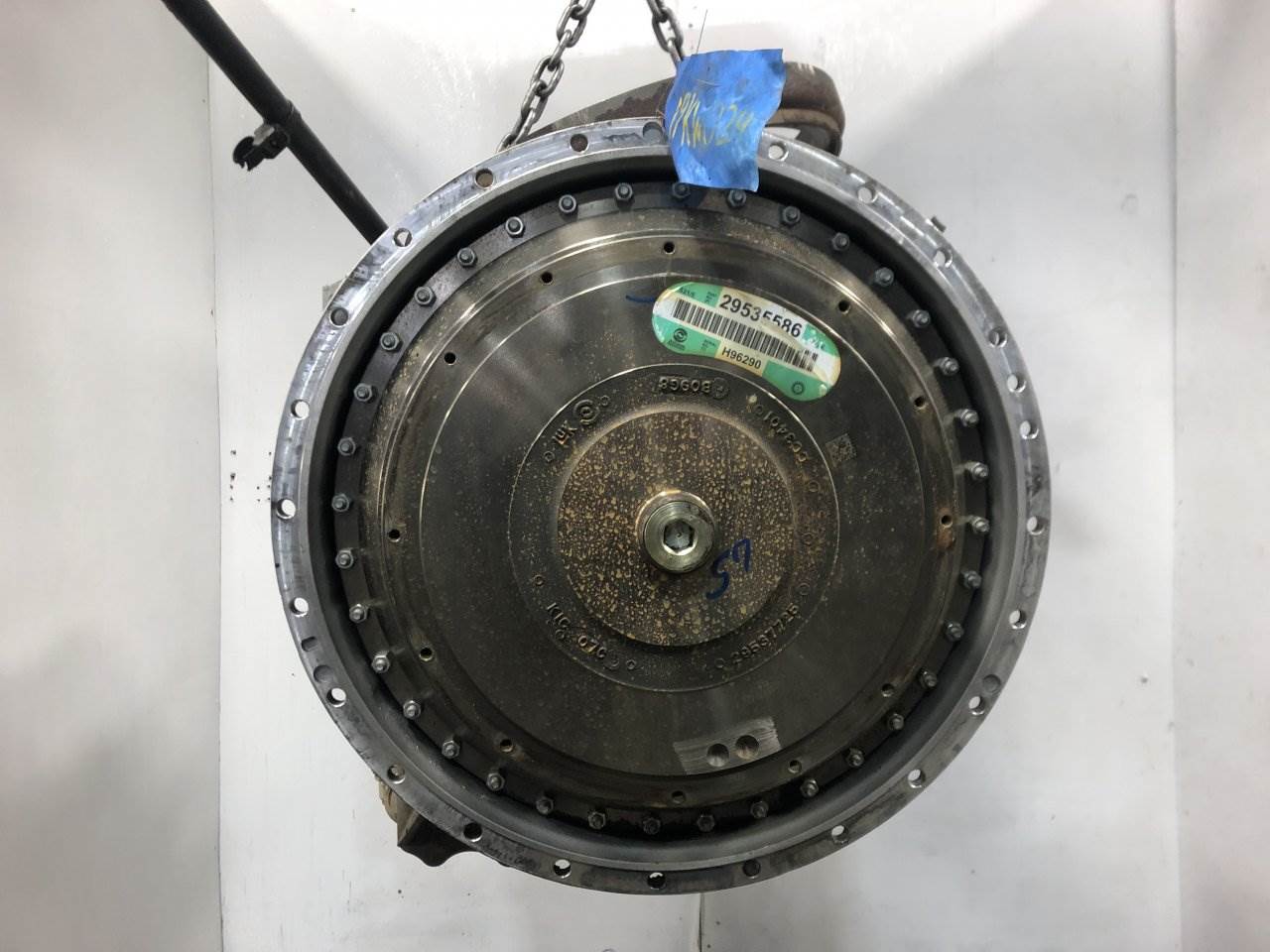

The Allison 4500 RDS transmission, a robust and reliable automatic transmission, boasts a complex internal structure designed for high torque applications. Understanding its technical specifications and internal workings is crucial for proper maintenance, troubleshooting, and overall operational efficiency. This section details the key specifications and provides a descriptive overview of the transmission’s internal components and their interactions.

Technical Specifications

The following table summarizes key technical specifications for the Allison 4500 RDS. Precise ratios can vary slightly depending on the specific application and gearing configuration. These values represent typical ranges.

| Specification | Value |

|---|---|

| Number of Forward Gears | 5 |

| Number of Reverse Gears | 1 |

| Input Torque Capacity (lb-ft) | 1150-1350 (depending on application) |

| Typical Gear Ratios | 1st: 4.26, 2nd: 2.62, 3rd: 1.59, 4th: 1.00, 5th: 0.74, Reverse: 4.00 (approximate values; may vary slightly) |

| Transmission Type | Fully automatic, planetary gearset |

| Fluid Type | TES-295 or equivalent |

| Weight (approximate) | 750-850 lbs (depending on configuration) |

Internal Components and their Functions

A cutaway diagram would show a complex arrangement of planetary gear sets, clutches, brake bands, and hydraulic control components. While a visual representation is not possible here, a detailed description of the major components and their functions follows.

The planetary gear sets are the core of the transmission’s gear-shifting mechanism. They consist of sun gears, planet gears, and ring gears, allowing for a variety of gear ratios through the engagement and disengagement of clutches and brake bands.

Clutches are multi-plate friction devices that connect or disconnect different components within the planetary gear sets, altering the gear ratio. They are hydraulically actuated.

Brake bands are friction bands that lock specific components within the planetary gear set, effectively changing the gear ratio. Like clutches, they are hydraulically actuated.

The hydraulic control system is responsible for managing the engagement and disengagement of clutches and brake bands based on the selected gear and the vehicle’s operating conditions. It uses a sophisticated system of valves, pumps, and sensors.

The input shaft receives power from the engine and transmits it to the planetary gear sets. The output shaft delivers power to the vehicle’s drive axle.

Gear Shifting Mechanism

The Allison 4500 RDS employs a sophisticated hydraulic control system to shift gears. The system uses input from various sensors (speed, throttle position, etc.) to determine the optimal gear for the current driving conditions. This information is then used to actuate the clutches and brake bands through a series of hydraulic valves. For example, shifting from 1st to 2nd gear might involve releasing a clutch connected to the ring gear and simultaneously engaging a clutch connected to the sun gear in the appropriate planetary gear set.

The precise sequence of clutch and brake band engagements and disengagements varies depending on the shift. This process is seamless and aims to optimize power delivery and fuel efficiency.

Troubleshooting and Common Issues

The Allison 4500 RDS, while a robust transmission, is susceptible to certain problems over time or due to improper maintenance. Understanding common issues, their symptoms, and diagnostic procedures is crucial for effective troubleshooting and minimizing downtime. This section details common problems, their causes, and solutions, providing a practical guide for maintenance and repair personnel.

Common Problems and Their Symptoms

Several factors can contribute to malfunctions within the Allison 4500 RDS. These range from relatively minor issues easily addressed through routine maintenance to more serious problems requiring specialized repair. Identifying the specific symptom is the first critical step in effective diagnosis.

Diagnostic Procedures

Accurate diagnosis requires a systematic approach. This often begins with a visual inspection for external leaks, damage, or loose connections. Further investigation may involve checking fluid levels and condition, performing pressure tests, and using diagnostic tools to retrieve and interpret electronic fault codes stored within the transmission’s control unit (TCM). Detailed diagnostic manuals and specialized software are often necessary for comprehensive troubleshooting.

Error Codes and Solutions

The Allison 4500 RDS utilizes electronic diagnostics to identify and report malfunctions. Understanding these codes is key to efficient repair. The following table Artikels some common error codes, their descriptions, potential causes, and recommended solutions. Note that this is not an exhaustive list, and consulting the official Allison service manual is crucial for complete troubleshooting.

| Error Code | Description | Potential Causes | Solutions |

|---|---|---|---|

| 1234 | Input Speed Sensor Fault | Faulty sensor, wiring harness damage, or TCM malfunction. | Inspect wiring harness for damage. Replace sensor if faulty. Check TCM for error codes and potential failure. |

| 5678 | Low Output Shaft Speed | Problems with output shaft, torque converter, or internal clutch pack. | Check for mechanical obstructions. Inspect torque converter for damage. Investigate internal clutch pack wear. |

| 9012 | Hydraulic Pressure Low | Low fluid level, pump failure, internal leakage, or clogged filter. | Check fluid level and condition. Inspect hydraulic pump and replace if necessary. Check for internal leaks. Replace filter. |

| 3456 | Governor Pressure Sensor Fault | Faulty sensor, wiring harness damage, or TCM malfunction. | Inspect wiring harness for damage. Replace sensor if faulty. Check TCM for error codes and potential failure. |

Maintenance and Repair Procedures

Proper maintenance of the Allison 4500 RDS transmission is crucial for ensuring optimal performance, extending its lifespan, and preventing costly repairs. Regular servicing, according to the manufacturer’s recommendations, involves a combination of inspections, fluid changes, and filter replacements. Ignoring these procedures can lead to premature wear and tear, resulting in reduced efficiency and potential catastrophic failure.

Routine Maintenance Procedures

Routine maintenance for the Allison 4500 RDS involves several key steps. These steps should be performed at the intervals specified in the owner’s manual. Failure to adhere to the recommended schedule may void warranties and significantly reduce the transmission’s lifespan. Safety precautions, including wearing appropriate personal protective equipment (PPE) such as gloves and safety glasses, are paramount throughout all maintenance procedures.

- Fluid Level Check: Check the transmission fluid level using the dipstick, ensuring the engine is running and the transmission is at operating temperature. The fluid level should be within the specified range on the dipstick. Low fluid levels indicate potential leaks or internal damage requiring immediate attention.

- Fluid and Filter Change: Replace the transmission fluid and filter according to the manufacturer’s recommended intervals. This typically involves draining the old fluid, replacing the filter, and refilling with the correct type and quantity of Allison-approved fluid. Using the incorrect fluid can severely damage the transmission.

- External Inspection: Visually inspect the transmission for leaks, damage, or loose connections. Pay close attention to seals, gaskets, and mounting bolts. Any signs of damage should be addressed promptly.

- Torque Converter Inspection (if accessible): If accessible, visually inspect the torque converter for any signs of damage or leaks. This component is critical for efficient power transfer.

Common Wear Part Replacement

Several components within the Allison 4500 RDS are subject to wear and tear and will eventually require replacement. The frequency of replacement depends on operating conditions and usage. Replacing these parts with genuine Allison parts or equivalent high-quality replacements is recommended to maintain optimal performance and reliability.

- Transmission Fluid: Regular fluid changes are essential to remove contaminants and maintain lubrication. The frequency depends on operating conditions and usage but is typically specified in the owner’s manual.

- Transmission Filter: The filter removes contaminants from the fluid, preventing damage to internal components. It should be replaced at the same time as the fluid change.

- Seals and Gaskets: Seals and gaskets can wear out over time, leading to leaks. These should be replaced as needed, typically during major repairs or overhauls.

- Clutch Packs and Friction Discs: These components wear down over time due to friction and heat. Replacement is typically required during major overhauls or when significant slippage is detected.

Tools and Equipment Required

Performing maintenance and repair on the Allison 4500 RDS requires specialized tools and equipment. Improper tools can damage the transmission or lead to inaccurate repairs. It’s essential to use the correct tools for each task.

Necessary tools include: transmission jack, torque wrenches (various sizes), fluid pump, filter wrench, various sockets and wrenches, drain pan, funnel, clean rags, and appropriate PPE (gloves, safety glasses, etc.). Access to a service manual and potentially specialized diagnostic equipment may also be necessary for more complex repairs.

Recommended Maintenance Intervals

Adherence to a regular maintenance schedule is vital for the longevity and performance of the Allison 4500 RDS. The following intervals are general guidelines and should be verified with the specific owner’s manual for the transmission. Operating conditions (heavy-duty use, extreme temperatures) may necessitate more frequent servicing.

- Fluid and Filter Change: Every 25,000 to 50,000 miles (or 1 to 2 years), depending on operating conditions.

- External Inspection: At each fluid and filter change.

- Major Overhaul: Every 250,000 to 500,000 miles (or as needed based on operational conditions and diagnostic findings).

Closure

The Allison 4500 RDS, with its specific number of forward gears and sophisticated shifting mechanism, represents a significant advancement in automatic transmission technology for heavy-duty vehicles. Understanding its operational characteristics, maintenance requirements, and troubleshooting procedures is essential for maximizing its lifespan and performance. This detailed examination provides a valuable resource for anyone working with or seeking to learn more about this reliable and efficient transmission system.

Detailed FAQs

What are the typical applications of the Allison 4500 RDS?

Medium-duty trucks, buses, and other heavy-duty vehicles requiring a robust and reliable automatic transmission.

What type of fluid does the Allison 4500 RDS use?

Consult the owner’s manual for the specific Allison-recommended transmission fluid.

How often should the Allison 4500 RDS be serviced?

Service intervals vary depending on operating conditions; refer to the owner’s manual for recommended schedules.

What are the common signs of a failing Allison 4500 RDS?

Rough shifting, slipping, unusual noises, fluid leaks, and illuminated warning lights are potential indicators of problems.