2 inches how long – 2 Inches: How Long Is It? This seemingly simple question opens a door to a surprisingly diverse exploration of measurement, perception, and practical application. From the everyday objects we encounter to the precision demanded in various industries, understanding the significance of two inches reveals its surprisingly widespread impact. We will examine its representation across different measurement systems, visualize its length using common items, and delve into its role in various fields.

This exploration will cover examples of objects approximately two inches long, comparisons with other units of measurement, and a detailed analysis of how this seemingly small length affects different contexts. We will also provide practical guidance on accurately measuring and representing two inches using various tools and techniques.

Two Inches in Different Contexts

Two inches, a seemingly small unit of measurement, holds significance across various fields and everyday life. Understanding its scale and applications provides a broader perspective on measurement and its practical implications. This section explores the context of two inches through examples, comparisons, and applications in different domains.

Examples of Objects Approximately Two Inches Long

The following table provides examples of common objects approximately two inches in length. Note that dimensions can vary slightly depending on the specific item and manufacturer.

| Name | Category | Typical Dimensions | Image Description |

|---|---|---|---|

| Standard AA Battery | Electronics | Approximately 2 inches in length, slightly varying by manufacturer | A cylindrical object, typically silver or brown in color, with a positive and negative terminal at either end. The surface is smooth, often with printed text indicating voltage and manufacturer information. |

| Thumb Drive (Small Size) | Electronics | Ranges from 1.5 to 2.5 inches, with 2 inches being a common length for smaller models | A small, rectangular device, often made of plastic, with a USB connector at one end and a protective cap at the other. May have a small loop for attaching to a keychain. |

| Standard Playing Card | Games | Approximately 2.5 inches wide and 3.5 inches long, with 2 inches representing roughly the width of the shorter side. | A rectangular card, typically made of thin cardboard, with various designs and symbols printed on both sides. The edges are typically smooth and may be slightly rounded. |

| Small Paperclip | Stationery | Approximately 2 inches long when fully extended | A thin wire bent into a loop at one end and a small hook or loop at the other. Typically made of metal, often with a shiny or slightly dull finish. |

Comparison of Two Inches to Other Units of Length

Understanding the relative size of two inches requires comparing it to other common units of measurement.

Two inches is equivalent to:

- Approximately 5.08 centimeters (cm)

- 0.1667 feet (ft)

- 1/6 of a foot

- About 1/36 of a yard

Significance of Two Inches in Various Fields

Two inches, while seemingly insignificant, plays a role in various specialized fields.

Specific examples include:

- Carpentry: Two inches can represent a common dimension for small woodworking projects, such as dowel joints or specific measurements in furniture design. Precise measurements at this scale are crucial for the structural integrity and aesthetic appeal of the final product.

- Medicine: In medicine, two inches might represent a crucial measurement for wound assessment, indicating the size or depth of an injury. Accurate measurement of this scale can influence treatment decisions.

- Electronics: The size and spacing of components on circuit boards often involve dimensions measured in inches or fractions of an inch. Two inches might represent the size of a small circuit board or the spacing between critical components.

Visualizing Two Inches: 2 Inches How Long

Understanding the length of two inches requires a practical approach, moving beyond abstract numerical representation to concrete visualization. This involves relating the measurement to familiar objects and mastering accurate measurement techniques.Visual Representation of Two Inches Using Common Household Items

Visual Representation of Two Inches

Imagine a simple illustration depicting several common household items lined up to visually represent two inches. The illustration would feature a standard-sized paperclip (approximately 1 inch long) placed next to a slightly shorter item, such as a small button or a domino tile, to complete the two-inch length. The paperclip would be clearly labeled as approximately one inch, and the combined length of the paperclip and the second item would be explicitly marked as two inches.

This visual aid provides a clear and relatable comparison, showing the relative size of two inches in context of everyday objects. The colors used in the illustration would be simple and contrasting to enhance clarity. For example, the paperclip could be silver, the button red, and the two-inch mark could be indicated by a bold black line.

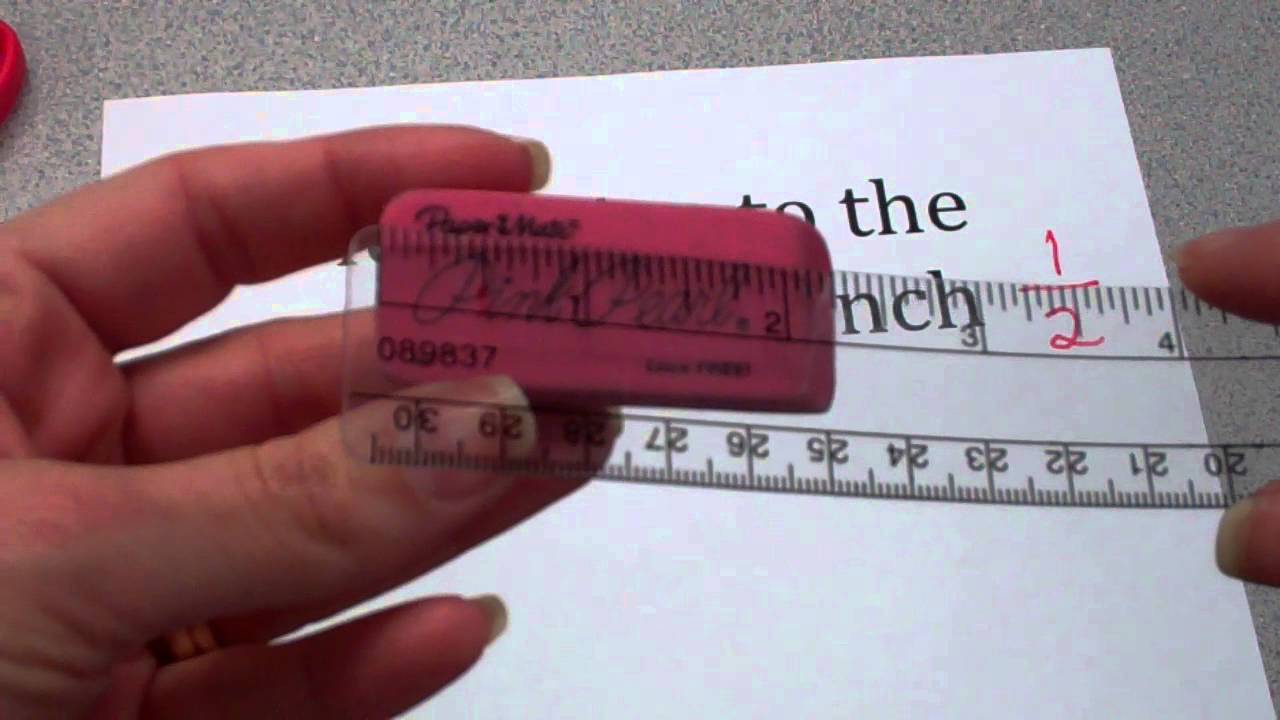

Measuring Two Inches with a Ruler

Accurate measurement is crucial for understanding length. The following steps Artikel the proper use of a ruler to measure two inches:

- Place the ruler flat against a surface. Ensure the zero mark aligns perfectly with the starting point of the measurement.

- Carefully locate the two-inch mark on the ruler. This is typically clearly indicated with a numbered or longer line segment.

- Identify the endpoint of the two-inch measurement. This will correspond to the two-inch mark on the ruler.

Drawing a Two-Inch Line with Different Tools

Different drawing tools require slightly different techniques for achieving precision.

Drawing with a Ruler and Pencil

- Place the ruler flat on the drawing surface. Align the zero mark with the desired starting point of the line.

- Hold the pencil at a consistent angle against the ruler’s edge, ensuring the pencil lead is directly above the two-inch mark.

- Lightly draw a straight line from the zero mark to the two-inch mark, using a steady hand and consistent pressure to create a clean, uniform line.

Drawing with a Straight Edge and Marker

The process is similar to using a ruler and pencil, but the broader marker tip might require slightly more care to maintain accuracy and avoid overshooting the two-inch mark. The process involves aligning the straight edge, positioning the marker, and carefully drawing a line from the starting point to the two-inch mark. Multiple light strokes may be necessary to ensure the line’s sharpness and evenness, particularly with thicker marker tips.

Two Inches in Everyday Life

Two inches, a seemingly insignificant length, plays a surprisingly significant role in numerous aspects of our daily lives. Its relevance stems from its frequent appearance in various contexts, where even small discrepancies can have noticeable effects. Understanding the implications of this small measurement across different situations is crucial for effective problem-solving and informed decision-making.The impact of a two-inch difference varies greatly depending on the context.

In some cases, it’s negligible; in others, it can be the difference between success and failure. This section will explore several common scenarios where two inches hold considerable weight.

Clothing Sizes and Fit

Clothing sizes often incorporate two-inch increments as a significant marker for alterations in fit. A two-inch difference in waist size, for instance, can mean the difference between a comfortable fit and an uncomfortable or ill-fitting garment. Similarly, sleeve length, inseam length for pants, and even the width of a shirt can be significantly affected by a two-inch variance. These differences directly impact comfort, appearance, and the overall functionality of the clothing.

For example, a two-inch difference in the inseam of trousers could result in a significant alteration in length, leading to tripping or bunching at the ankles.

Tool Dimensions and Precision

In many trades and DIY projects, precision is paramount. A two-inch discrepancy in the measurement of a piece of wood for carpentry, for instance, could lead to significant problems with the final product. Similarly, in mechanical engineering, a two-inch error in the dimension of a part could render the entire assembly unusable. This highlights the critical importance of accurate measurement in contexts where precision is paramount.

The tolerance for error varies greatly depending on the application; some situations demand extreme accuracy, while others allow for greater leeway.

Everyday Objects and Measurements, 2 inches how long

Beyond specialized fields, two inches manifests in many everyday objects and measurements. The depth of a shelf, the width of a picture frame, or the height of a small appliance are all often specified in inches. A two-inch variation in any of these dimensions could influence functionality or aesthetics. For instance, a two-inch shallower shelf might not accommodate certain items, and a two-inch narrower picture frame might not adequately display a given image.

These examples show how even seemingly minor differences in two-inch measurements can affect the practical usability and perceived quality of objects in our daily lives.

Two Inches and Measurement Systems

Two inches, a seemingly small unit of length, highlights the complexities and historical evolution of measurement systems. Understanding its representation in different systems provides insight into the global standardization efforts and the diverse ways humans have quantified distance throughout history. This section will compare and contrast the representation of 2 inches within the imperial and metric systems, explore the historical development of the inch, and provide a clear conversion table for various units.The inch, a unit within the imperial system, has a long and complex history, unlike the more systematically designed metric system.

Its origins are shrouded in antiquity, with its length evolving over centuries and varying across different regions and time periods. In contrast, the metric system, based on the meter, offers a more consistent and easily scalable system, with clear relationships between units like centimeters and millimeters. The difference reflects the contrasting approaches to standardization: a gradual, regionally influenced evolution versus a deliberate, globally coordinated system.

The Inch’s Historical Context

The inch’s origins are not precisely defined, but its development is intertwined with the evolution of other units of measurement within the British Imperial system. Early iterations of the inch were often based on readily available physical references, such as the width of a thumb (hence the term “inch”). These early definitions lacked precision and varied considerably. Over time, attempts were made to standardize the inch, leading to variations in official definitions across different countries and periods.

The current definition of the inch is based on its relationship to the meter within the International System of Units (SI), with one inch defined as exactly 2.54 centimeters. This standardization, however, came after centuries of inconsistent definitions.

Two Inches in Different Units

The following table provides a comparison of 2 inches in various units of measurement. Note that the conversions are based on the modern, standardized definition of the inch.

| Unit | Abbreviation | Conversion Factor | Equivalent Length (2 inches) |

|---|---|---|---|

| Centimeter | cm | 1 inch = 2.54 cm | 5.08 cm |

| Millimeter | mm | 1 inch = 25.4 mm | 50.8 mm |

| Foot | ft | 12 inches = 1 ft | 0.167 ft |

| Yard | yd | 36 inches = 1 yd | 0.056 yd |

Array

The seemingly insignificant length of two inches finds surprisingly widespread application across various fields, impacting precision manufacturing, tool design, and everyday objects. Its utility stems from its convenient size for numerous tasks and its role as a readily divisible unit within larger measurement systems. The precision required for maintaining a 2-inch measurement varies significantly depending on the application, highlighting the importance of understanding tolerances in different contexts.

The precision of a 2-inch measurement directly affects the functionality and quality of many manufactured goods. In some cases, deviations of even a fraction of a millimeter can render a product unusable. Conversely, in other applications, a slightly larger or smaller measurement might be acceptable without compromising performance. Understanding these tolerances is critical for cost-effective and efficient production.

Tools and Instruments Utilizing 2 Inches

Many tools and instruments either measure 2 inches precisely or utilize this measurement in their design and function. The precise nature of these tools demands high manufacturing accuracy to ensure reliability and precision.

- Small wrenches and screwdrivers: Many hand tools, particularly those intended for smaller tasks, are designed with 2-inch handles for comfortable grip and leverage.

- Measuring tools: Rulers and tape measures frequently incorporate 2-inch markings as a standard unit for quick measurement estimations. Some specialized calipers might feature a 2-inch jaw opening for specific applications.

- Electronic components: Certain circuit boards or electronic components may have specific dimensions that include 2-inch lengths or widths, demanding tight tolerances during manufacturing to ensure proper functionality and compatibility.

- Medical instruments: Specific surgical tools or probes might be designed with 2-inch working lengths for targeted procedures. Precision in this case is paramount for patient safety and effective treatment.

Precision’s Impact on Manufacturing Processes

The required precision for a 2-inch measurement significantly impacts various manufacturing processes. The level of tolerance needed depends heavily on the intended use of the final product.

In the production of precision instruments, such as those used in aerospace or microelectronics, maintaining a 2-inch dimension within tolerances of a few thousandths of an inch is critical. This necessitates the use of advanced manufacturing techniques like CNC machining and high-precision measuring equipment. Conversely, the production of less critical items might allow for larger tolerances, impacting the choice of manufacturing methods and overall cost.

For instance, a 2-inch wooden dowel might tolerate a variance of several millimeters without affecting its intended function.

Tolerances in Different Industries

Tolerances associated with a 2-inch measurement vary considerably across different industries, reflecting the diverse requirements for precision and functionality. These tolerances are often expressed as plus or minus a specific value, indicating the acceptable range of variation from the nominal 2-inch measurement.

| Industry | Typical Tolerance (inches) | Rationale |

|---|---|---|

| Aerospace | ±0.001 | Critical for safety and performance of aircraft components. |

| Microelectronics | ±0.0005 | Essential for the proper functioning of electronic circuits. |

| Automotive | ±0.005 | Balances precision with cost-effectiveness. |

| Woodworking | ±0.05 | Tolerances are relatively larger due to the nature of the material and manufacturing processes. |

In conclusion, while seemingly insignificant at first glance, two inches holds a surprisingly significant role in numerous aspects of our lives. From the everyday objects we use to the precise requirements of manufacturing processes, understanding the concept and application of this unit of measurement provides a valuable perspective on the world around us. The ability to accurately visualize, measure, and apply this length highlights the importance of precise measurement in various fields and everyday scenarios.

Detailed FAQs

What is the equivalent of 2 inches in centimeters?

Approximately 5.08 centimeters.

How many millimeters are in 2 inches?

50.8 millimeters.

Is 2 inches a standard size for any common item?

While not a universally standardized size, many small items, such as certain screws, bolts, or electronic components, are close to or precisely 2 inches in length.

What is the tolerance typically allowed for a 2-inch measurement in manufacturing?

The acceptable tolerance varies greatly depending on the industry and application. It could range from +/- 0.01 inches to +/- 0.25 inches or more.