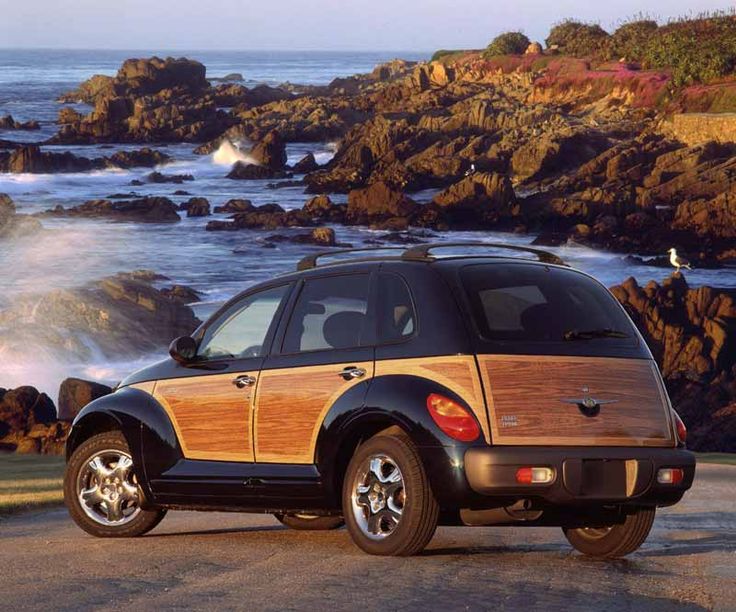

04 pt cruiser woody how is the wood decal installed – 04 PT Cruiser Woody: Wood Decal Installation explores the process of applying wood grain decals to a 2004 Chrysler PT Cruiser Woody. This guide covers decal types, surface preparation, application techniques (wet and dry), troubleshooting common issues, and post-installation care. Understanding these steps ensures a successful and long-lasting installation, transforming the appearance of your vehicle.

From choosing the right decal material and preparing the vehicle’s surface to mastering application techniques and addressing potential problems, this comprehensive guide offers a step-by-step approach to achieve a professional-looking finish. We’ll examine the nuances of working with curved surfaces and offer solutions for common installation challenges, including air bubbles and wrinkles. The goal is to provide the knowledge and confidence needed for a successful DIY project.

Understanding the 04 PT Cruiser Woody Decal

The 2004 PT Cruiser Woody’s distinctive feature is its wood-grain decal, which significantly impacts the vehicle’s aesthetic appeal. Understanding the materials, types, and installation challenges associated with this decal is crucial for both owners seeking repairs or customization and those interested in the vehicle’s design history.The materials used in the factory-installed 2004 PT Cruiser Woody decal typically consist of a durable vinyl film printed with a wood-grain pattern.

This vinyl is designed to be weather-resistant and UV-resistant to withstand the elements. The adhesive backing ensures the decal adheres securely to the vehicle’s body. Some aftermarket decals may utilize similar materials, although the quality and longevity can vary significantly.

Decal Materials and Types

The primary material is a high-quality vinyl, chosen for its flexibility, durability, and resistance to fading and cracking from sun exposure. The printed wood grain pattern is typically a high-resolution image, designed to mimic the appearance of real wood. While the factory decal likely uses a specific vinyl formulation optimized for automotive applications, aftermarket options may differ in their material composition, potentially affecting their lifespan and resistance to wear.

Different aftermarket decals may offer variations in the wood grain pattern itself – some might mimic lighter woods like birch, others darker woods like walnut, and still others may offer more stylized or abstract wood-grain designs.

Factory Versus Aftermarket Decals

Factory-installed decals, applied during the vehicle’s manufacturing process, generally offer a superior finish and more precise fit. The edges are typically seamlessly integrated with the vehicle’s body curves, and the color and texture consistency are usually more uniform. Aftermarket decals, while offering a more affordable alternative, may exhibit inconsistencies in color, texture, and alignment. They might also have visible edges or imperfections, especially when applied to complex curves.

The adhesive quality can also vary, potentially leading to peeling or lifting over time. The lifespan of a factory decal is generally longer due to superior materials and application techniques.

Challenges of Decal Installation on Curved Surfaces

Applying a wood decal to the curved surfaces of a PT Cruiser presents several challenges. The decal needs to conform smoothly to the body’s contours without wrinkling, bubbling, or creating air pockets. This requires careful preparation of the surface, including thorough cleaning and degreasing. The application process itself demands precision and patience to avoid misalignment or trapping air bubbles.

Heat guns are often used to help the vinyl stretch and conform to the curves, but improper use can damage the decal or the vehicle’s paint. The curves of the PT Cruiser, particularly around the wheel wells and along the sides, present especially challenging areas for even application. Poor installation can result in a less-than-professional appearance, highlighting the importance of expertise or careful attention to detail.

Preparation for Decal Installation

Proper surface preparation is crucial for a successful and long-lasting decal installation on your 2004 PT Cruiser Woody. A clean, smooth, and properly temperature-controlled surface ensures the decal adheres correctly and prevents peeling or bubbling. Failing to adequately prepare the surface can lead to premature decal failure and necessitate costly reapplication.Preparing the surface involves a multi-step process designed to remove any contaminants that might interfere with the adhesive.

This includes dirt, grease, wax, and old adhesive residue. The goal is to create a perfectly clean and dry surface for optimal decal adhesion. The environmental conditions also play a significant role in the success of the installation.

Surface Cleaning, 04 pt cruiser woody how is the wood decal installed

Thorough cleaning is paramount. Begin by washing the area where the decal will be applied with a mild detergent and lukewarm water. Use a soft sponge or wash mitt to avoid scratching the paint. Rinse thoroughly with clean water, ensuring all soap residue is removed. Pay close attention to any crevices or areas where dirt might accumulate.

After washing, carefully dry the surface with a clean, lint-free microfiber cloth. Avoid leaving any moisture behind, as this can affect the decal’s adhesion.

Contaminant Removal

After the initial wash, inspect the surface for any remaining contaminants such as wax, grease, or old adhesive residue. Wax can be removed using a dedicated wax and grease remover, available at most auto parts stores. Follow the product instructions carefully. For stubborn adhesive residue, use a plastic scraper or a specialized adhesive remover, again following the product instructions to avoid damaging the paint.

Always test any cleaning product on an inconspicuous area first to ensure it doesn’t harm the paint.

Surface Temperature and Weather Conditions

Ideal conditions for decal installation include a surface temperature between 65°F and 85°F (18°C and 29°C). Avoid applying decals in direct sunlight, as the heat can cause the adhesive to cure too quickly and potentially lead to imperfections. Similarly, avoid installing decals in cold or humid conditions, as this can affect adhesion and drying time. The ideal weather is a slightly overcast day with moderate temperatures.

Choosing the right time of day can significantly impact the outcome of the installation. For example, applying the decal in the morning shade after the dew has evaporated would be preferable.

Surface Preparation Checklist

Prior to beginning the decal installation, ensure all the following steps have been completed:

- Vehicle surface thoroughly washed with mild detergent and lukewarm water.

- Surface rinsed completely and dried with a lint-free cloth.

- All wax, grease, and old adhesive residue removed.

- Surface temperature is within the recommended range (65°F-85°F).

- Work area is free from direct sunlight and excessive humidity.

- All necessary tools and materials are gathered and ready for use.

Decal Application Methods

Applying a decal, especially a large one like the PT Cruiser woody decal, requires careful technique to achieve a professional, bubble-free finish. Two primary methods exist: wet application and dry application, each with its own advantages and disadvantages. Choosing the right method and tools is crucial for a successful installation.

Wet Application Method

The wet application method involves applying the decal to a surface that has been lightly sprayed with soapy water. This allows for repositioning and minimizes the risk of trapping air bubbles. The soapy water acts as a lubricant, allowing the decal to slide into place easily. This method is generally preferred for larger decals or those with complex designs.

| Step | Action | Tools | Considerations |

|---|---|---|---|

| 1 | Clean the application surface thoroughly with a mild detergent and water. Allow to dry completely. | Mild detergent, clean water, microfiber cloth | A clean surface is crucial for proper adhesion. |

| 2 | Lightly spray the application surface with a solution of water and mild dish soap. | Spray bottle, mild dish soap, water | Avoid over-spraying; a light mist is sufficient. |

| 3 | Carefully peel the backing paper from the decal, exposing the adhesive side. | None | Start at a corner and slowly peel back, avoiding creases. |

| 4 | Position the decal on the surface, ensuring it is correctly aligned. | Measuring tape (optional) | Take your time and reposition as needed; the soapy water allows for adjustments. |

| 5 | Using a squeegee or applicator, smooth the decal from the center outwards, working to expel all water and air bubbles. | Squeegee or felt applicator | Apply firm, even pressure; avoid excessive force. |

| 6 | Remove any excess soapy water with a clean, dry microfiber cloth. | Microfiber cloth | Gently blot, do not rub. |

| 7 | Allow the decal to dry completely before removing the clear transfer tape (if applicable). | None | Drying time will vary depending on temperature and humidity. |

Dry Application Method

The dry application method involves applying the decal directly to the surface without any soapy water. This method is faster but requires more precision and skill, as repositioning is limited once the decal is placed.Advantages of the dry method include faster application time and a potentially stronger initial adhesion. Disadvantages include a higher risk of air bubbles and wrinkles, and less room for error in placement.

Application Tool Comparison

Several tools can be used to apply decals, each with its own benefits. Squeegees, typically made of rubber or plastic, provide even pressure and are effective at removing air bubbles. Felt applicators are gentler on the decal surface and minimize the risk of scratching. The choice of tool depends on the decal material and the applicator’s experience level.

For delicate decals, a felt applicator is generally preferred, while squeegees are suitable for most applications.

Smoothing Out Air Bubbles and Wrinkles

Air bubbles and wrinkles can be smoothed out during the application process using a squeegee or applicator. For small bubbles, gently press the bubble with the tool to work the air out towards the edge of the decal. For larger bubbles or wrinkles, carefully lift a corner of the decal using a razor blade or a very fine needle, then use the squeegee to smooth it back down, working out the air from the center outwards.

Avoid pulling or stretching the decal as this can cause damage. If the bubble is persistent, carefully pierce it with a fine needle to release the trapped air. Always work slowly and methodically to avoid damaging the decal.

Troubleshooting Common Installation Issues

Installing a wood decal on a 2004 PT Cruiser Woody, while seemingly straightforward, can present several challenges. Understanding these potential problems and their solutions is crucial for a successful and aesthetically pleasing outcome. Proper preparation and careful application techniques significantly minimize the risk of encountering these issues.

Several common problems can arise during the installation of a wood decal, primarily related to adhesion, alignment, and the appearance of the finished product. These issues often stem from inadequate surface preparation, incorrect application techniques, or environmental factors. Addressing these issues promptly and effectively is key to achieving a professional-looking result.

Air Bubbles

Air bubbles trapped beneath the decal are a frequent problem. They detract from the overall appearance, creating unsightly bumps and imperfections. These bubbles typically form when the decal isn’t properly smoothed down during application, leaving air pockets between the adhesive and the vehicle’s surface.

To remedy air bubbles, a small needle or pin can be carefully used to puncture the bubble, allowing the air to escape. Immediately smooth the area with a squeegee or soft cloth, working the air out from the center of the bubble towards the edges. For larger bubbles, lifting a small section of the decal edge, releasing the trapped air, and then carefully smoothing it back down might be necessary.

Preventing air bubbles involves using a squeegee to thoroughly smooth the decal from the center outwards during application, ensuring complete contact with the surface.

Wrinkles and Creases

Wrinkles or creases can appear during the application process, often caused by uneven application or the decal not being properly aligned before adhering. These imperfections are difficult to correct once the decal is fully adhered, highlighting the importance of careful and methodical application.

Minor wrinkles might be smoothed out using a heat gun set on a low setting. The heat helps relax the vinyl, allowing it to conform to the surface. However, if the wrinkles are severe, the decal might need to be removed and reapplied. Preventing wrinkles requires careful planning and alignment before application, ensuring the decal is positioned correctly before fully adhering it to the vehicle’s surface.

Slowly and evenly applying the decal, starting from one edge and working your way across, minimizes the risk of creases.

Peeling Edges

Peeling edges are a common issue resulting from insufficient adhesion, often caused by a dirty or inadequately prepared surface. Environmental factors such as extreme temperatures can also contribute to this problem.

If edges start peeling, clean the area thoroughly with a suitable cleaner to remove any dirt or debris. Then, apply a small amount of adhesive promoter to improve the bond between the decal and the surface. Firmly press the peeling edge back down, ensuring good contact with the underlying surface. To prevent peeling, always ensure the surface is clean and dry before application.

Applying the decal in a controlled environment, avoiding extreme temperatures, also helps maintain adhesion.

Troubleshooting Guide

The following bulleted list summarizes the common problems, their causes, and solutions to aid in effective troubleshooting during wood decal installation:

- Problem: Air Bubbles; Cause: Inadequate smoothing during application; Solution: Puncture bubble with needle, smooth with squeegee.

- Problem: Wrinkles/Creases; Cause: Uneven application, improper alignment; Solution: Use heat gun (low setting) or reapply decal.

- Problem: Peeling Edges; Cause: Insufficient adhesion, dirty surface; Solution: Clean surface, apply adhesive promoter, press down firmly.

Post-Installation Care and Maintenance

Proper care and maintenance are crucial for extending the lifespan and preserving the appearance of your PT Cruiser Woody decal. Neglecting these steps can lead to premature fading, peeling, or damage, diminishing the aesthetic appeal of your vehicle. This section Artikels best practices for maintaining your decal’s quality and vibrancy.Protecting your wood grain decal from the elements is paramount.

UV rays from the sun are particularly damaging, causing the colors to fade and the decal to become brittle over time. Extreme temperatures, both hot and cold, can also negatively impact its adhesion and longevity. Regular cleaning is essential to remove dirt, grime, and other contaminants that can compromise the decal’s integrity.

Effects of Weather Conditions on the Decal

Exposure to direct sunlight accelerates the degradation process of the decal’s adhesive and inks. Prolonged exposure to intense UV radiation can cause noticeable fading and discoloration, especially in lighter wood tones. Similarly, extreme heat can soften the adhesive, potentially leading to lifting or bubbling, while extreme cold can make the decal brittle and prone to cracking. To mitigate these effects, consider parking your vehicle in shaded areas whenever possible, especially during peak sun hours.

In regions with harsh winters, garage parking or the use of protective covers can help minimize damage from freezing temperatures.

Cleaning the Decal

Regular cleaning is essential for maintaining the appearance and longevity of your wood grain decal. However, improper cleaning techniques can cause damage. Avoid abrasive cleaners, harsh chemicals, and high-pressure washing, as these can strip away the decal’s protective layer or even remove it entirely.

Recommended Cleaning Products and Techniques

For routine cleaning, a gentle car wash soap diluted with water is recommended. Apply the solution using a soft sponge or microfiber cloth, avoiding excessive scrubbing. Rinse thoroughly with clean water and dry the decal gently with a clean, soft towel or chamois. For stubborn dirt or grime, a dedicated vinyl or plastic cleaner specifically designed for automotive use can be employed.

Always test any cleaning product on a small, inconspicuous area of the decal first to ensure it doesn’t cause discoloration or damage. Avoid using solvents, waxes, or polishes containing harsh chemicals, as these can react negatively with the decal’s material. After cleaning, consider applying a UV protectant spray specifically formulated for automotive vinyl to help shield the decal from the damaging effects of the sun.

This extra layer of protection can significantly extend the lifespan of your decal.

Visual Guide

This section provides a step-by-step description of the PT Cruiser woody decal installation process, guiding you through each stage to achieve a professional-looking result. Careful attention to detail and precision are key to a successful installation.The process involves preparing the surface, applying the decal, and smoothing out any air bubbles. Visual cues, such as consistent edge alignment and the absence of wrinkles or creases, will indicate proper installation.

Understanding these cues will help you identify and correct any issues during the application process.

Decal Alignment and Placement

Begin by carefully positioning the decal on the vehicle’s surface, ensuring it is centered and aligned with existing body lines or features. Visualize the final result before committing to adhesion. Gently lower the decal onto the surface, starting from one edge and slowly working your way across, using a squeegee or similar tool to smooth out any air bubbles or wrinkles.

Proper alignment will result in a seamless and even appearance, with the decal’s edges following the contours of the vehicle’s body. Misalignment will be evident as an uneven or skewed appearance of the wood grain pattern, with the decal edges not matching the vehicle’s lines.

Appearance of a Correctly Installed Decal

A correctly installed decal will exhibit a smooth, even surface, free of wrinkles, air bubbles, or creases. The wood grain pattern will appear continuous and uninterrupted, seamlessly integrating with the vehicle’s body. The edges of the decal will be cleanly aligned with the vehicle’s contours, creating a natural and professional look. The color and texture of the decal will appear consistent throughout its surface, and the overall appearance will be pleasing to the eye.

Appearance of an Incorrectly Installed Decal

Conversely, an incorrectly installed decal will present several visual imperfections. Wrinkles or creases will be visible, distorting the wood grain pattern. Air bubbles trapped beneath the decal will appear as unsightly bumps on the surface. The edges may be uneven or misaligned, creating a jagged or unprofessional appearance. The wood grain pattern might appear distorted or broken in places.

The overall look will be unsatisfactory and visually unappealing, indicating the need for removal and reapplication.

Final Summary

Successfully installing a wood decal on your 2004 PT Cruiser Woody enhances its aesthetic appeal. This guide provided a structured approach, from initial surface preparation to post-installation care. By following the Artikeld steps and troubleshooting tips, you can achieve a professional-looking result that will stand the test of time. Remember, careful preparation and attention to detail are key to a successful installation.

Proper care and maintenance will further prolong the life and beauty of your upgraded PT Cruiser.

Clarifying Questions: 04 Pt Cruiser Woody How Is The Wood Decal Installed

What type of squeegee is best for decal application?

A felt-edged squeegee is generally preferred to avoid scratching the decal or vehicle surface.

Can I install the decal in direct sunlight?

No. Direct sunlight will cause the adhesive to dry too quickly, leading to wrinkles and air bubbles. Work in shade or on a cloudy day.

How long should I wait before washing my car after decal installation?

Wait at least 24-48 hours to allow the adhesive to fully cure before washing the vehicle.

What should I do if I get an air bubble during installation?

Carefully pierce the bubble with a pin and gently smooth out the air using a squeegee. If large, consider carefully lifting an edge and reapplying.